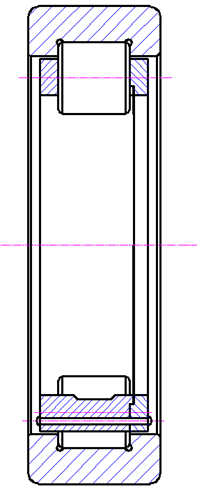

For single row CRB, rollers are always guided by solid rib. Ring with rib, cylindrical roller and cage are separable to another ring. This is convenient for installation and un-installation especially two rings are interference fitting per load situation. Single row CRB is ok for heavy radial load and high speed. NU Structure: NU outer ring has two solid rib and inner ring doesn’t have. The shaft can move bi-direction axially against housing. So this NU is for non-fixed end bearing. |

|

·

| NU Structure: NU outer ring has two solid rib and inner ring doesn’t have. The shaft can move bi-direction axially against housing. So this NU is for non-fixed end bearing. |

| N structure: inner ring has two solid ribs and outer ring doesn’t have. The shaft can move bi-direction axially against housing. So it is for non-fixed end bearing. |

| NJ structure: Outer ring has two solid ribs and inner ring has one. So this is for one direction axial positioning. |

·

| NUP structure: outer ring has two solid ribs, inner ring has one solid rib and one non-integrated rib with loose fit. This is ok for fixed end bearing, and can position the shaft in two direction axially. |

| NUB structure: outer ring has two solid ribs, inner ring doesn’t have ribs but two sides protrudes to outer ring. The shaft can move bi-direction axially against housing. This for non-fixed end bearing. |

·

| NB structure: inner ring has two solid ribs, outer ring doesn’t have ribs but both sides protrude. The shaft can move bi-direction axially against housing. This for non-fixed end bearing. |

| NJP structure: outer ring has two solid ribs, inner ring has one loose fit rib ring. This is for one direction shaft positioning. |

·

| NJF structure: inner ring and outer ring both has one solid rib. This is for one direction shaft positioning. |

| NF structure: inner ring has two solid ribs and outer ring has one. This is for one direction shaft positioning. |

·

| NFP structure: same like NF structure, but outer ring has one loose fit rib ring not integrated rib. |

| NP structure: inner ring has two solid ribs and outer ring has one solid rib and loose fit rib ring. This is for both direction shaft positioning axially. |

·

| RNU structure: if the shaft can be quenched and ground, then it is better to use RNU bearing outer ring has two solid ribs together with roller and cage. Without inner ring, bigger shaft diameter is possible and increase rigidity, moreover the shaft displacement against housing is only limited by the raceway width. If raceway made with right dimension and shape accuracy, then we can see good running accuracy. RNU can be offered with special requirement. |

·

| RN Structure: RN has no outer ring. This structure is for high load capability and limited space if housing can be quenched and ground to work as raceway. One typical application is planetary gear support. RN can be offered with special requirement. |

·

| Retaining Ring: HJ retaining ring is designed to position NU and NJ type CRB. We will use this retaining ring for heavy load application, but not NUP type CRB because full width inner ring of NU and NJ type CRB can offer more steady support than narrower NUP type. NU+HJ structure: we can use NU and HJ to position shaft in one direction, and corresponds to NJ type. It is not permitted to install two HJ retaining ring at both sides of inner ring because this will possible cause roller gets stuck. |

·

| NJ+HJ structure: NJ and HJ type together can act as positioning bearing for shaft positioning in both direction axially. |

·

| Full complement single row CRB This kind of with full complement bearing rollers are guided by ribs. Full complement CRB has very high load capability and rigidity because fill in as more as possible rollers. Limited to kinematics situation, their limit speed is not as high as cage bearing. It is for half-positioning bearing. It is designed inner ring with two ribs, outer ring with single rib and flat retaining ring and full complement rollers. The distance bearing can move axially decided by the gap between roller end and retaining ring. |

·

| Disc type cage CRB This brass disc type cage avoids roller contact. This design is in between full complement bearing and caged bearing design. Roller guided by outer ring stiff rib. Inner ring is separable, and can install inner ring and outer ring respectively. It can be used as half-positioning bearing. Outer ring is radial split, and will be connected by ring-like snap ring during installation. Inner ring is with sing rib. Roller is longer and bigger, then increase load capability dramatically. Cage is disc type with unique design and thinking compare with traditional disc type cage. |

·

| Split single row CRB: according to requirement, design split bearing for fixed end and non-fixed end. This will be used with housing and have advantage from installation and seal. |

·

· Clearance

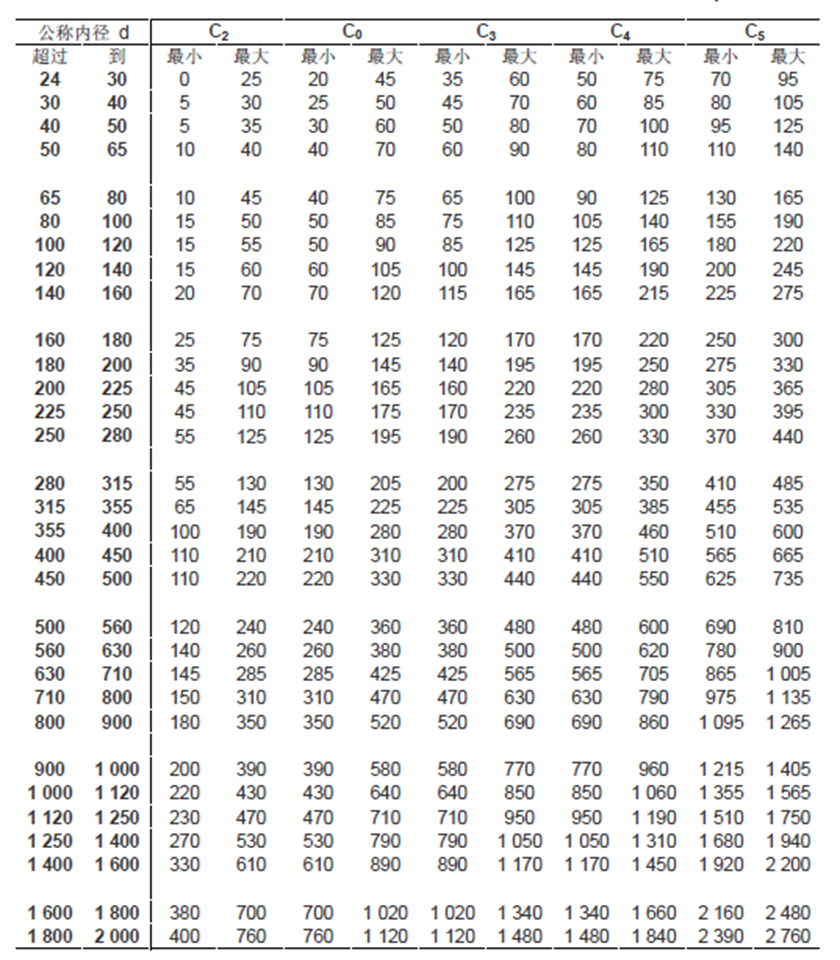

· Single row CRB radial clearance follow GB/T4604-1993/ISO5753:1991(R2001). See table 1.

· Table 1: Single row CRB radial clearance: μm

·  ·

·

Contact: Mrs.Catherine

Phone: +86 15140413495

E-mail: sales@wsabearing.com

Add: Wawo Industrial Zone, Wafangdian City, Dalian China