Introduction

In the world of industrial machinery, where performance and reliability are paramount, there's an often-overlooked hero that plays a crucial role - split bearings. These unassuming components are the backbone of many heavy-duty applications, quietly improving efficiency and reducing maintenance hassles. In this article, we'll delve into the world of split bearings, exploring what they are, how they work, and the remarkable benefits they bring to various industries.

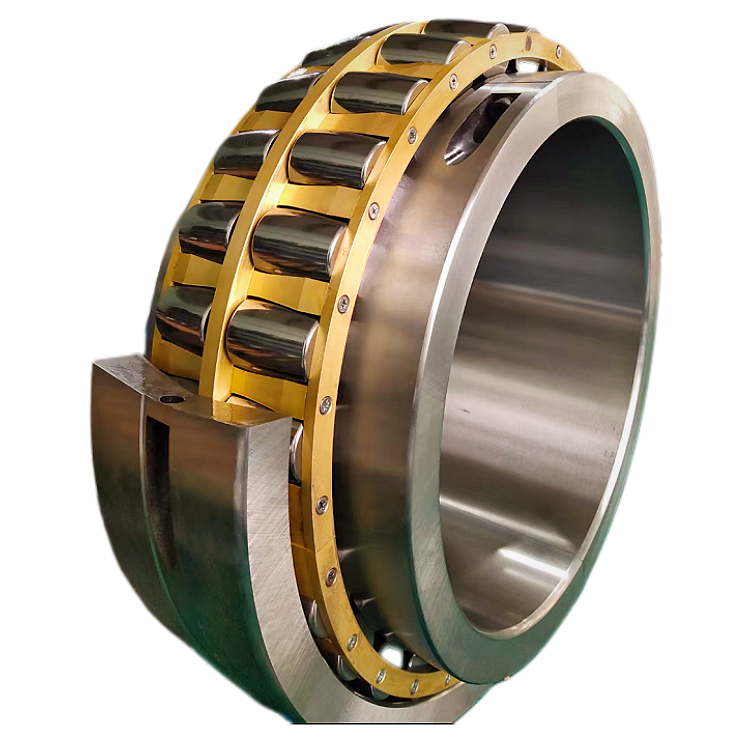

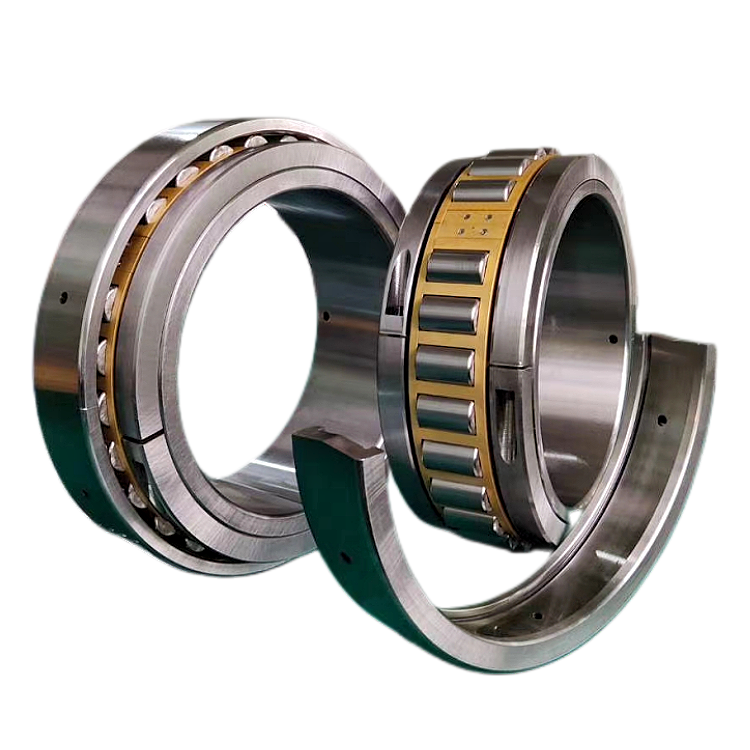

Split bearings, also known as split roller bearings or split spherical roller bearings, are a specialized type of rolling-element bearing. What sets them apart from traditional bearings is their unique design. Unlike one-piece bearings, split bearings are divided into two separate halves, which can be easily installed and removed from the shaft or housing without the need to disassemble surrounding equipment.

How Do Split Bearings Work?

The magic of split bearings lies in their ingenious design. They consist of two identical halves that fit together seamlessly when installed on a shaft. These halves are secured in place with bolts or clamping mechanisms, effectively creating a complete bearing unit. When properly mounted, split bearings provide all the benefits of a traditional bearing, such as reducing friction and facilitating smooth rotation.

Benefits of Split Bearings

Ease of Installation and Maintenance: Split bearings are a game-changer when it comes to installation and maintenance. Unlike solid bearings, there's no need to dismantle machinery or shafts to replace or service them. This drastically reduces downtime and labor costs.

Versatility: Split bearings are adaptable and can be used in a wide range of applications, from conveyors and gearboxes to heavy-duty equipment like paper machines and mining equipment.

Improved Reliability: Split bearings are known for their reliability and durability. They can handle heavy loads and harsh operating conditions, making them an ideal choice for demanding industrial environments.

Cost Savings: Reduced downtime, easier maintenance, and extended service life translate to significant cost savings over the long term.

Environmental Benefits: By minimizing the need for frequent replacements and reducing waste, split bearings contribute to a more sustainable approach to industrial operations.

Applications

Split bearings find applications in a multitude of industries, including:

Mining: Handling the extreme loads and harsh conditions encountered in mining operations.

Pulp and Paper: Ensuring smooth paper production by supporting massive rolls and rollers.

Marine: Supporting critical equipment in marine vessels and offshore platforms.

Steel Mills: Withstanding the heavy-duty requirements of steel manufacturing processes.

Wind Energy: Enabling the efficient rotation of wind turbine components.

Conclusion

In the world of industrial machinery, split bearings might be the unsung heroes, but their impact is undeniable. Their ability to simplify installation, reduce downtime, and enhance reliability makes them an essential component in various applications. By choosing split bearings, industries can not only improve their operational efficiency but also reduce costs and contribute to a more sustainable future.

As technology continues to advance, split bearings remain a shining example of how innovative engineering solutions can transform industries and keep the wheels of progress turning. So, the next time you see a smoothly operating piece of heavy machinery, remember that split bearings might be the silent force behind its flawless performance.

Contact: Mrs.Catherine

Phone: +86 15140413495

E-mail: sales@wsabearing.com

Add: Wawo Industrial Zone, Wafangdian City, Dalian China