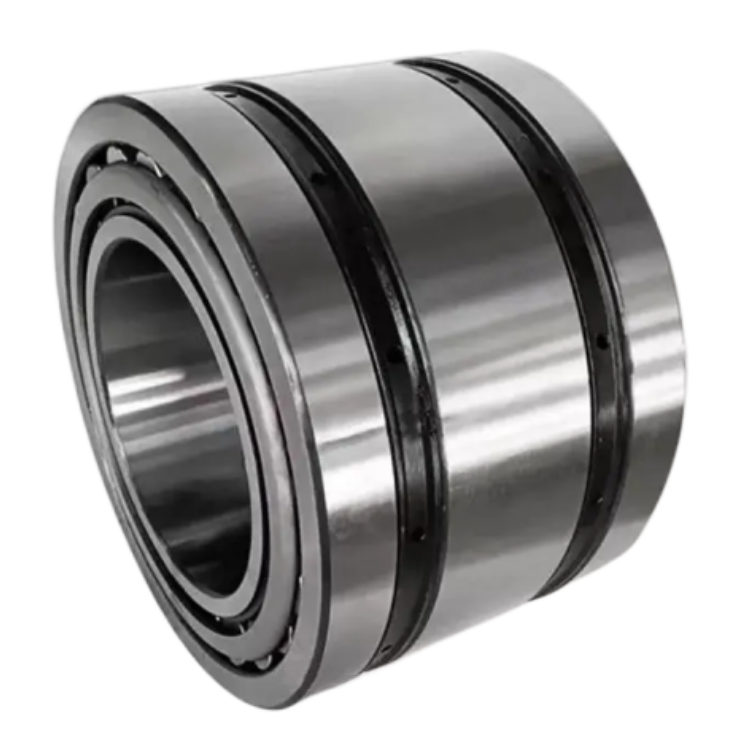

Four-row taper roller bearings, featuring four rows of tapered rollers, excel at distributing radial and axial loads. Their intricate structure involves inner and outer rings and a cage to maintain roller spacing. These bearings have diverse applications: steel mills for steel processing, mining equipment, wind turbines, railways, rolling mills in metalworking, and construction machinery. They ensure efficient performance under heavy loads and dynamic conditions, contributing to the smooth operation of machinery across various industries.

Bearings play a crucial role in various industries, ensuring the smooth operation of machinery and equipment. One such remarkable type is the four-row taper roller bearing, designed to handle significant radial and axial loads while maintaining stability and precision. In this article, we delve into the structure and applications of these versatile components.

Structure of Four-Row Taper Roller Bearings:

Four-row taper roller bearings are engineered with a complex design that enables them to distribute both radial and axial loads effectively. They consist of four rows of rollers arranged in a manner that allows for controlled movement and enhanced load-bearing capacity.

Inner and Outer Rings: The inner and outer rings of a four-row taper roller bearing provide structural support and guide the rolling elements. These rings are usually made from high-quality bearing steel to ensure durability and performance.

Rolling Elements: The rollers are designed with a taper, which allows them to accommodate both radial and axial loads. The taper angles are optimized to minimize friction and wear while maintaining proper contact with the inner and outer rings.

Cage: To maintain proper spacing and alignment of the rollers, a cage is often used in four-row taper roller bearings. The cage is typically made of steel, brass, or other materials, and it prevents direct contact between the rollers, reducing friction and heat generation.

Applications of Four-Row Taper Roller Bearings:

Four-row taper roller bearings find their utility in a range of industries due to their unique design and load-bearing capabilities:

Steel Mills: In steel mills, four-row taper roller bearings are employed to support heavy loads encountered in rolling and processing steel. These bearings handle both radial and axial loads during continuous casting, rolling, and other production processes.

Mining Equipment: Mining operations subject machinery to harsh conditions and heavy loads. Four-row taper roller bearings are utilized in equipment like conveyors, crushers, and large excavators, ensuring reliable performance under demanding conditions.

Wind Turbines: The wind energy industry relies on bearings that can handle substantial loads and vibrations. Four-row taper roller bearings are used in wind turbine gearboxes, contributing to the efficient conversion of wind energy into electricity.

Railway Applications: In the railway sector, these bearings are employed in axle boxes of locomotives and passenger cars. Their ability to withstand both radial and axial loads makes them suitable for the dynamic conditions of rail transportation.

Rolling Mills: Four-row taper roller bearings are essential components in rolling mills for the metalworking industry. They facilitate the precise movement of rolls, ensuring the accurate shaping and reduction of metal sheets or bars.

Construction Machinery: Construction equipment, such as cranes and excavators, rely on four-row taper roller bearings to manage the heavy loads and vibrations encountered during building and infrastructure projects.

In conclusion, four-row taper roller bearings stand as a testament to the innovation and engineering prowess of the bearing industry. Their intricate design and robust construction make them indispensable for applications involving substantial radial and axial loads. From steel mills to wind turbines, these bearings play a vital role in diverse industries, enabling efficient and reliable operation under demanding conditions.

Contact: Mrs.Catherine

Phone: +86 15140413495

E-mail: sales@wsabearing.com

Add: Wawo Industrial Zone, Wafangdian City, Dalian China