SRB is kind of bearing can take bigger load. SRB has two rows roller, outer ring has one spherical raceway and inner ring has two raceway tilts certain angle to bearing center line, SRB has self-alignment capability. SRB misalignment angle is 1°~2.5°normally, but varies per dimension series and load situation. Symmetrical spherical roller can self-align at outer ring raceway, then can compensate deflection and misalignment fitting. SRB not only can take radial load, but also both direction axial load, and has shock resistance capability. SRB is design ed for high load capability because they have as more as possible rollers with certain length, SRB is also suitable for heavy load. The perfect adaptation between roller and raceway guarantees well-distributed force.

|

|

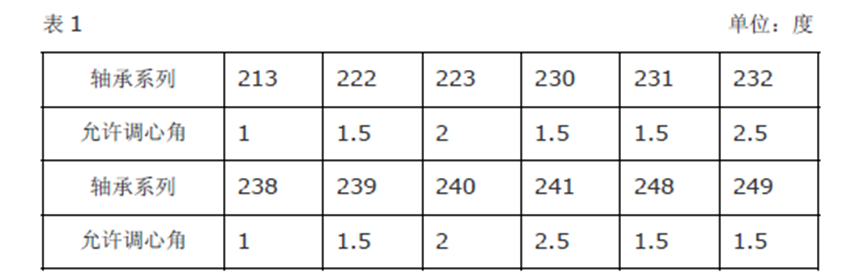

Permitted misalignment

SRB misalignment angle is 1°~2.5°normally, but varies per dimension series and load situation. Details see table 1.

Structure and features: Structure and features: SRB has symmetrical and dissymmetrical structure per roller section shape. Dissymmetrical spherical roller is early design. Symmetrical roller bearing has overall improvement design and parameters perfection, this design can take more axial load comparing with dissymmetrical design, also can work under high speed and low working temperature. SRB can be categorized C type and CA type per whether inner ring has rib and different cage, CA type features with symmetrical roller and inner ring has ribs both sides and use turning cage. C type has symmetrical roller and moving retainer ring, no ribs on inner ring, has stamped cage. To improve lubrication, can offer bearing with circular groove and holes suffixed with W33. For convenience of removal, installation and change bearing, offer bearing with taper bore normally 1:20 (except for 240 and 241 series) suffixed with K, also can supply taper 1:30 bearing for special requirement suffixed with K30 (240 and 241 series ). Taper bore bearing can be installed to taper shaft through locking nut, or fix to cylindrical shaft with adapter sleeve. Taper bore SRB can be supplied with locking adapter sleeve, locking nut, adjusting washer and removal sleeve. Adapter sleeve and withdrawal sleeve should be order separately. |

CA型 |

C型 | |

| Heavy load SRB: Heavy load SRB: for heavy load application which normal design is not suitable, we use heavy load SRB design through removing middle retainer ring on the basis of C type, decreasing contact angle and designing bigger and longer roller, then increase radial load capability. (see below picture) |

| Single row SRB: kind of design between SRB and CRB has certain alignment angle, takes bigger radial load and light axial load disadvantage. |

| Sealed SRB: for heavy load, harsh environment or special seal requirement, can offer built-in contact seal SRB. The geometry is the same like non-seal bearing and can replace non-seal bearing at many situation. Alignment angle 0.5°, working temperature -20°C~110°C. This SRB filled with certain amount anti-corrosion grease. |

SRB for vibration screening machine:

for vibration screening machine and other vibration machine bearing, offering symmetrical roller SRB with two independent outer ring guided solid turning cage. Or symmetrical roller SRB with fixed middle rib which can take axial load, two inner ring guided solid cage and group 3 or group 4 even bigger radial clearance, bore diameter tolerance is not standard. Advantage: high load, anti-shock, anti-vibration, less friction, low temperature and long life.

|

|

SRB for elevator:

draw up elevator bearing quality system and follow this during manufacturing strictly. The lift elevator tractor has noise level limit for this kind of bearing, so we stipulate definite vibration noise level, also enhance rings and roller roughness grade, enhance cage manufacturing standard and some running accuracy. Set higher standard for material selection and control, as well as heat treatment method and control.

| Split SRB: this is good choice for some difficult to reach bearing position with solid bearing, or application needs a lot timing and man power for maintenance and cost much for down time such as long shaft or crankshaft. For this kind of installation, this bearing has split inner ring, split outer ring and wide inner ring with snap ring, so it is easy to install and fit. Some split SRB key dimension is same like taper bore SRB and straight bore SRB. Split bearing inner ring and cage are horizontal split. Split bearing inner ring is wider than solid bearing because of snap ring. Steel plant demands not to remove driving system when change rotary furnace drive end bearing, split bearing can help for this situation. Nevertheless, normally split bearing is only for spare part due to the cost. |

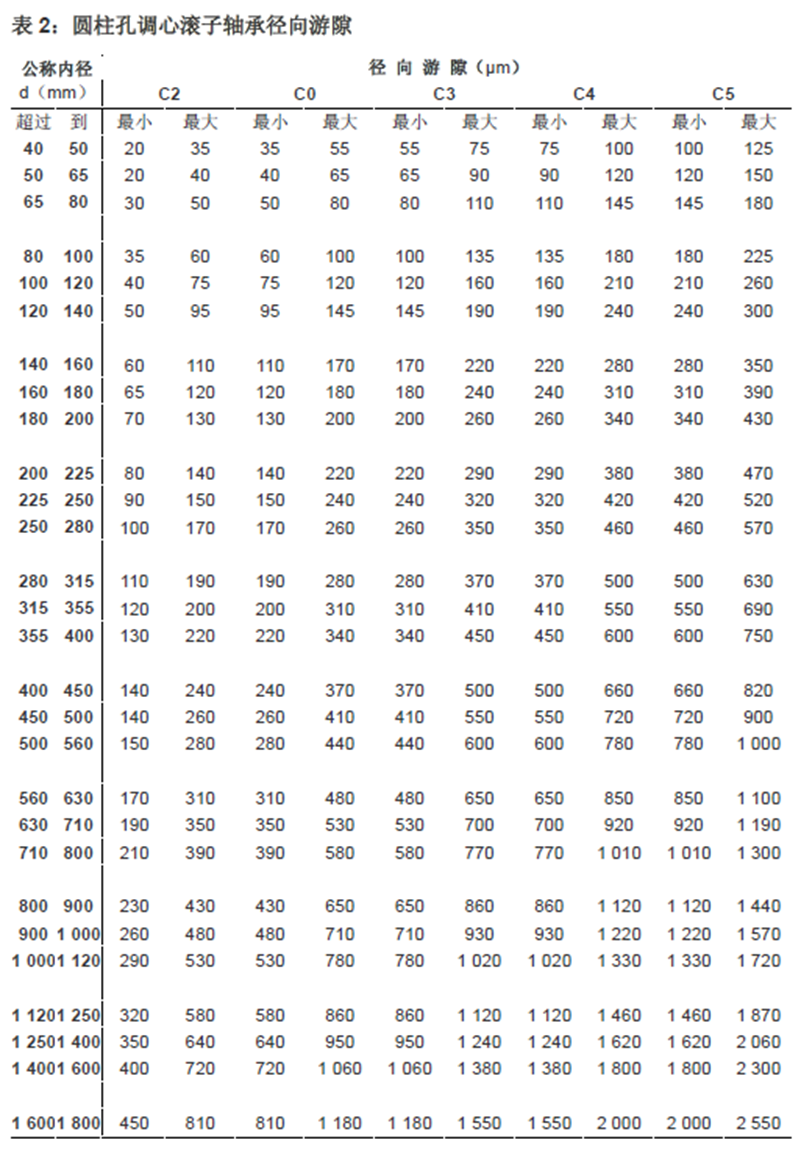

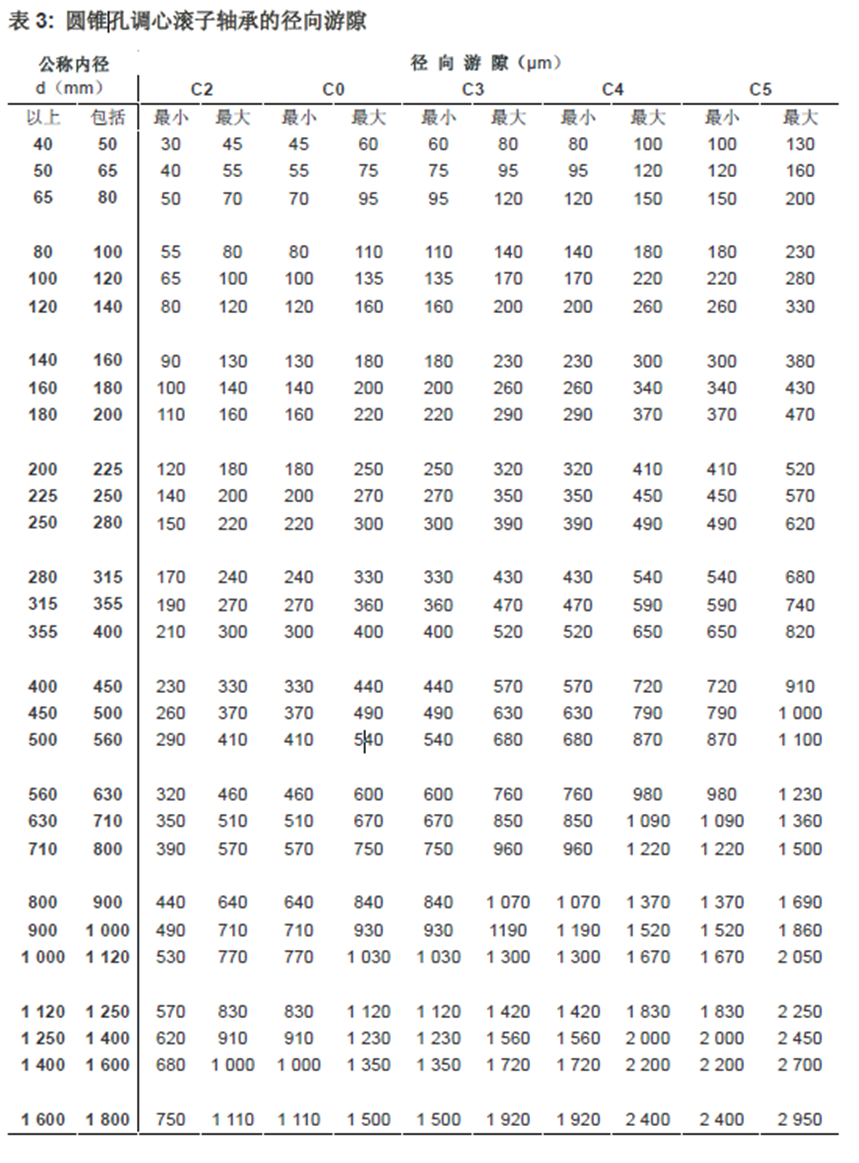

Clearance:

SRB radial clearance is C0 normally, and other clearance need to be claimed in the order. Radial clearance follows GB/T4604-1993/ISO5753-1991. Straight bore SRB radial clearance see table 2, taper bore table 3.

Minimum load

To ensure bearing functions while rotates, SRB has to take some minimum load especially run high speed or high accelerator at load direction and fast changing load. The inertia of roller and cage plus lubrication friction have negative effect on bearing rotation, possible damaging sliding happen between roller and raceway.

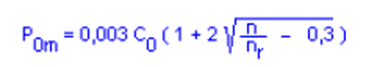

Formula to calculate necessary minimum load:

P0m=0.02C0 to estimate.

Which

P0m=min equivalent static load,kN

C0=basic rated static load ,kN(see production list)

In some application, it is not possible to reach or exceed minimum load. But bearing is with lubrication and can compromise lower minimum load. When the load n/nr ≤ 0.3 timeP0m = 0.003 C0 ,and 0.3 < n/nr ≤ 2.

Which

P0m=min equivalent static load,kN

C0=basic rated static load ,kN(see production list)

n=speed,r/min

nr=limit speed under oil lubrication,r/min(see bearing list)

When start up at low temperature or high viscosity lubrication, may need higher P0m=0.01C0 minimum load. Bearing support parts dead weight and alien force should be bigger than minimum load. If this is not the case, we have to add additional radial load.

Axial load

SRB can take some axial load precondition that Fa ≤ 2tgα·Fr,or else bearing will be damaged due to one row roller over load and one row idling.

Equivalent dynamic load

For SRB takes dynamic load,

When Fa/Fr ≤ e, P = Fr + Y1Fa

When Fa/Fr > e, P = 0,67 Fr + Y2Fa

Coefficient e, Y1 and Y2 see bearing list.

Bearing equivalent load

For SRB takes static load

P0 = Fr + Y0Fa

Coefficient Y0 see bearing list.

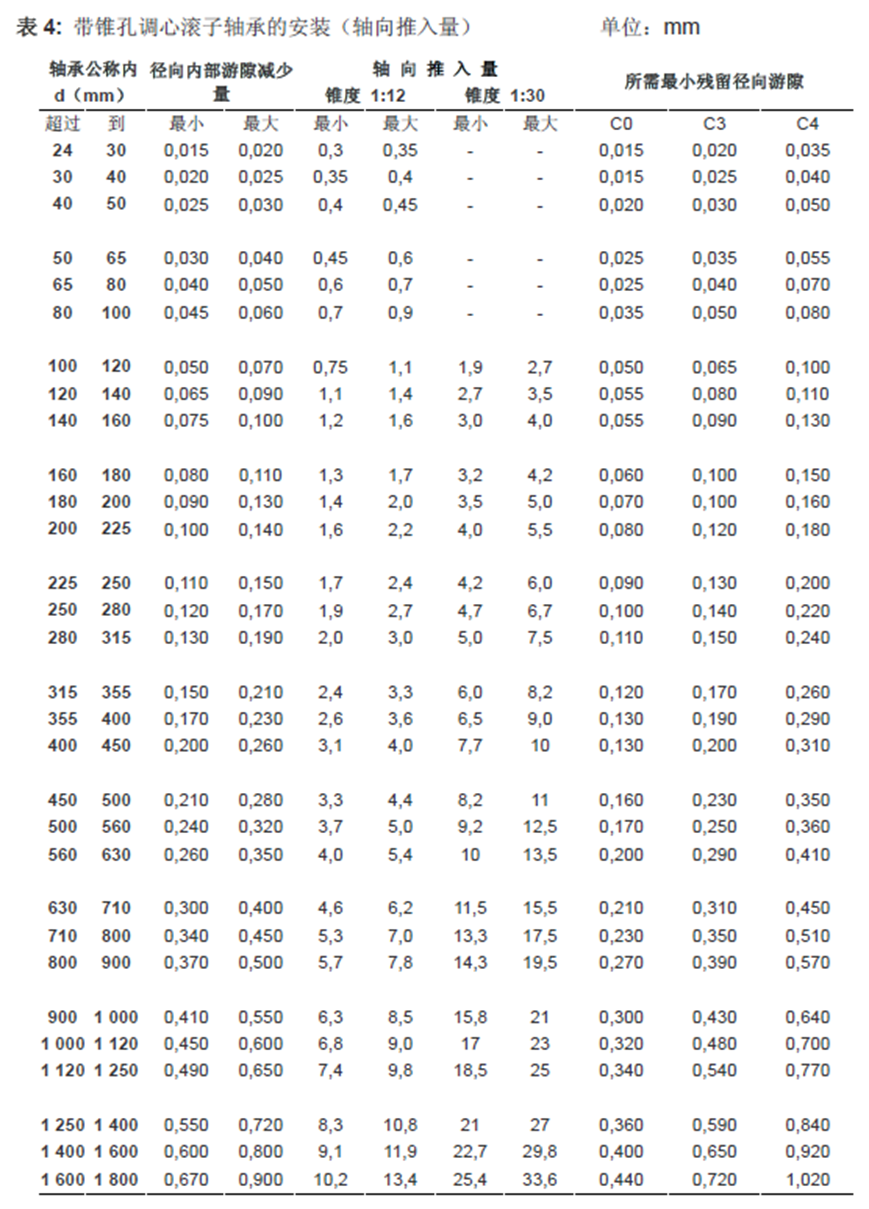

Taper bore bearing installation

Taper bore bearing installation is always with interference fitting. Lower radial internal clearance or inner ring axial displacement is the key way to adjust interference fitting.

Technique to install taper bore SRB:

--measure decrease of clearance;

--measure locking angle of locking nut;

--measure axial displacement;

--measure inner ring expansion。

The installation of self-aligning roller bearing with tapered hole (axial pushing amount) is shown in the table 4.

Contact: Mrs.Catherine

Phone: +86 15140413495

E-mail: sales@wsabearing.com

Add: Wawo Industrial Zone, Wafangdian City, Dalian China