Tapered roller bearing belongs to separate bearing, and the inner and outer rings of the bearing Single row tapered roller bearings can withstand radial load and axial load in a single direction. When the bearing bears radial load, an axial component will be generated, so another bearing that can bear the axial force in the opposite direction is needed to balance.

Single Row Tapered Roller Bearings

WSA taper roller bearings have the rolling elements under the form of frustum of cone. They roll on tapered surface which, if extended, converges towards a single point on the bearing axis. The rollers are guided tangentially by the cage and axially by the big rib of the inner ring, on which they have contact. As between rollers and raceways there is linear contact, they can take heavy radial loads. They can also take heavy axial or combined loads, depending on the contact angle caused by the tapered elements. The contact angle is the one of the outer raceway generatrix.

The single row taper roller bearings are of separable design, which means the outer ring/cup and the inner ring/cone with rollers and cage assembly can be separately mounted. The two parts are interchangeable.

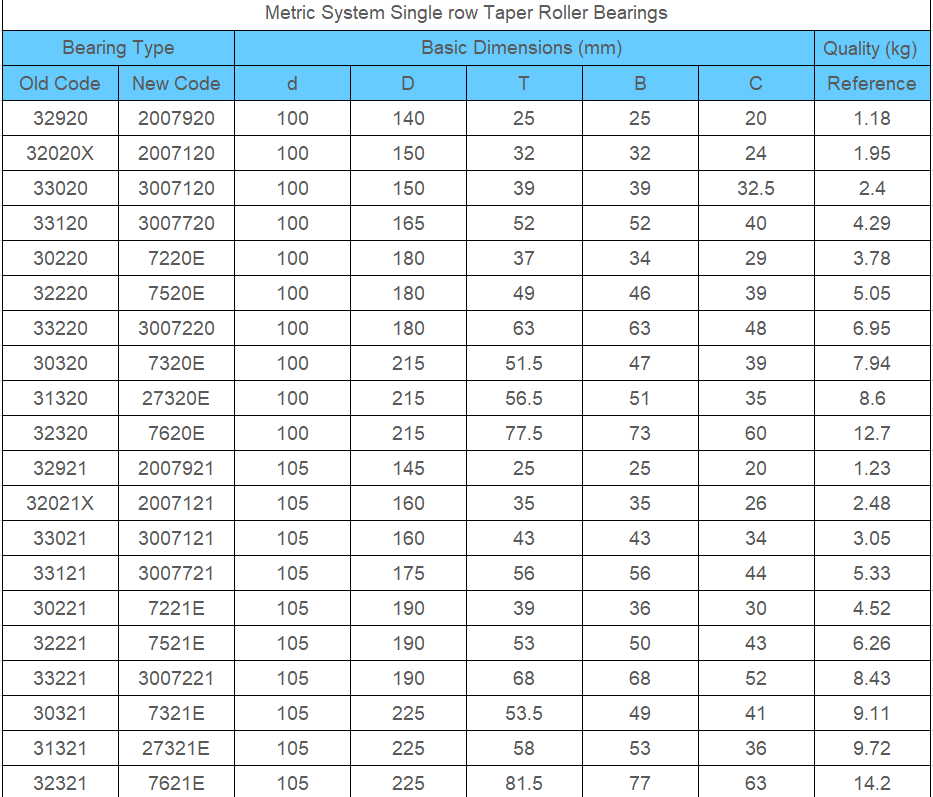

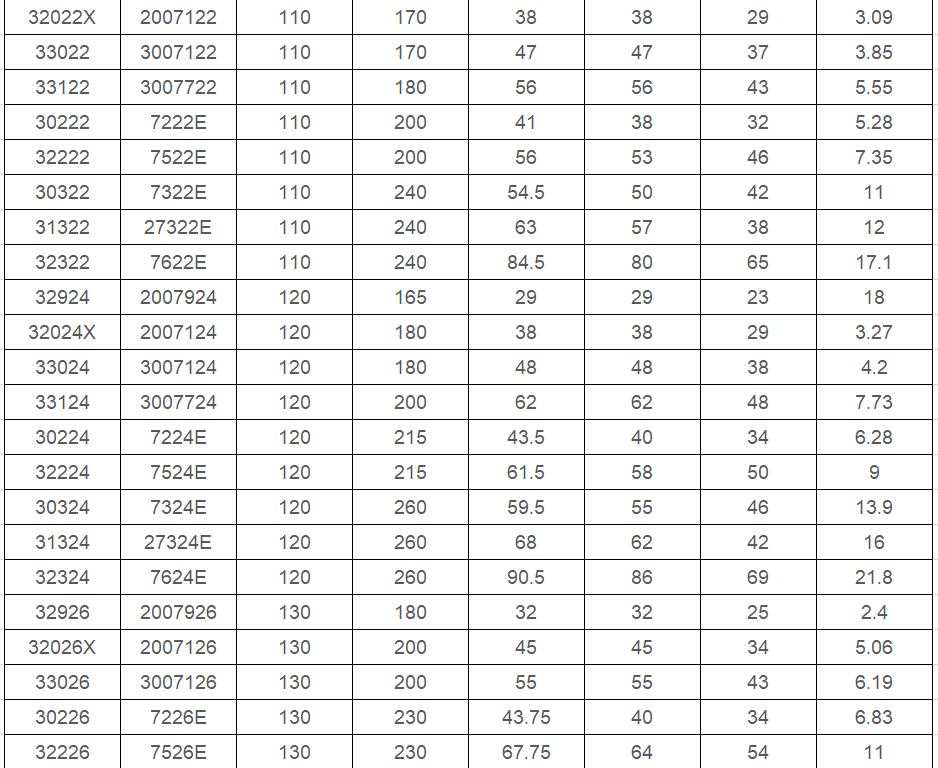

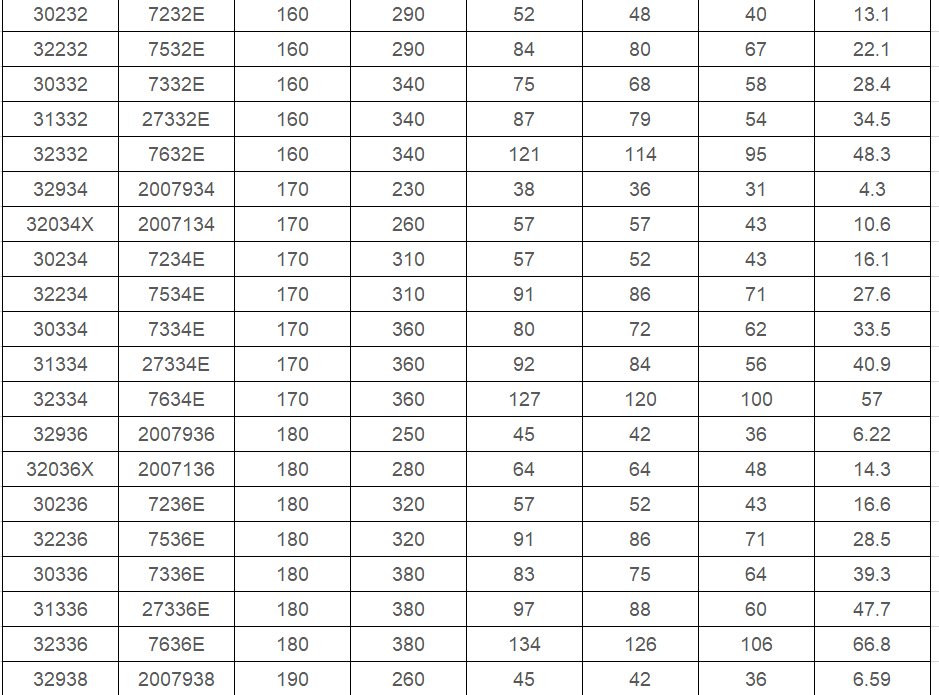

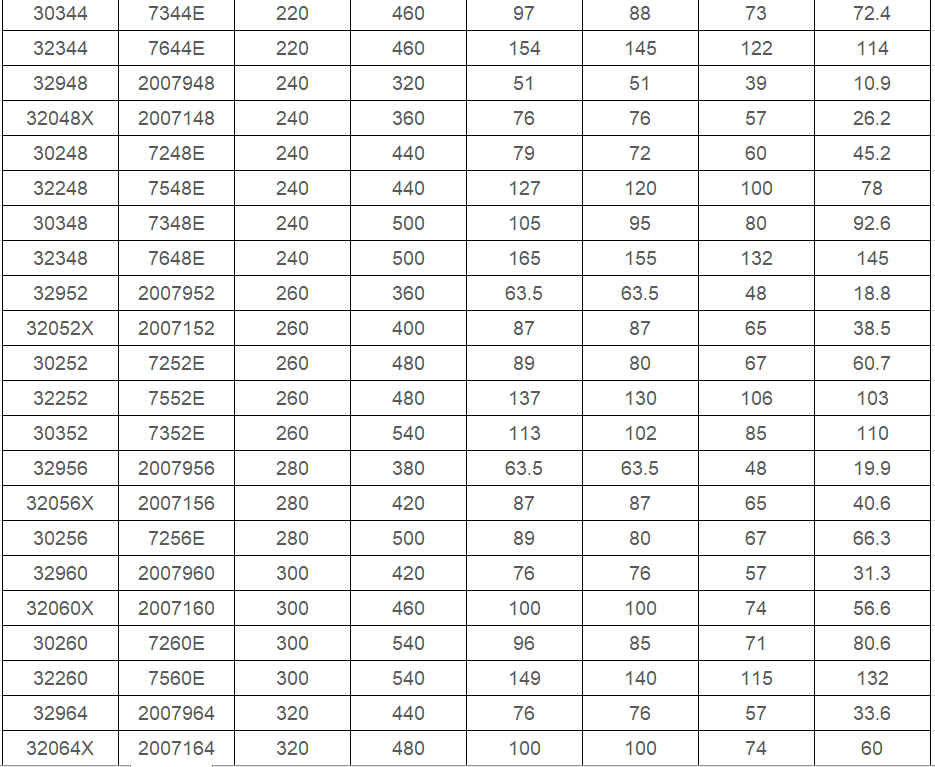

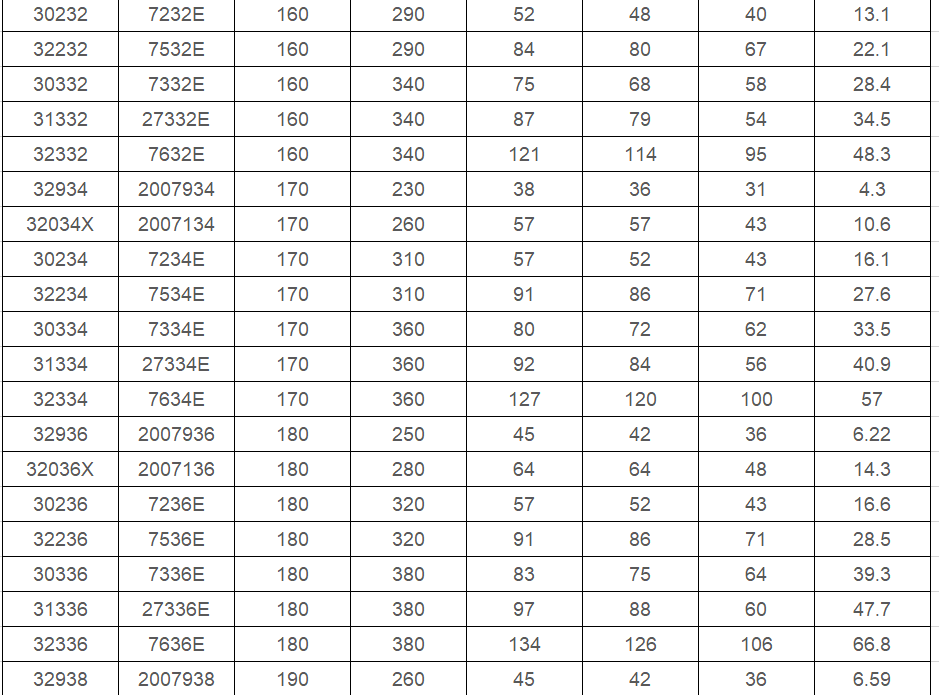

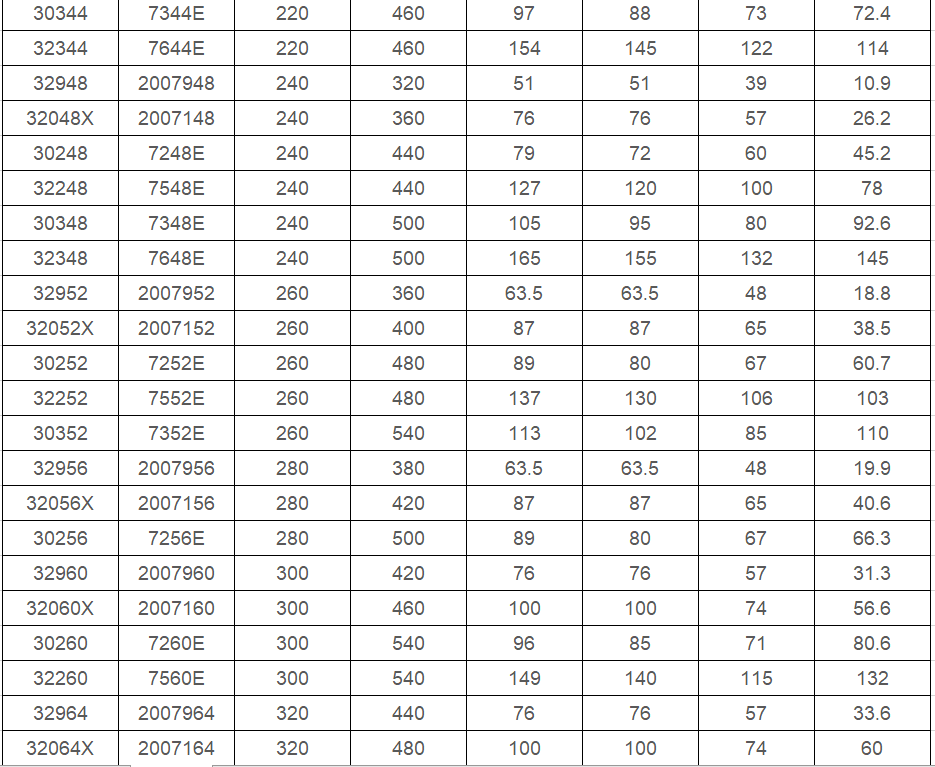

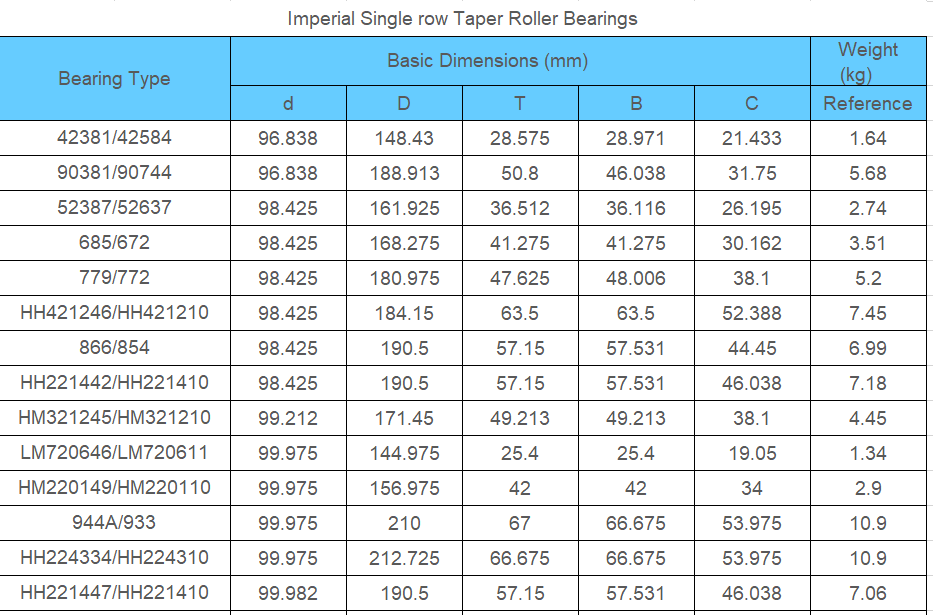

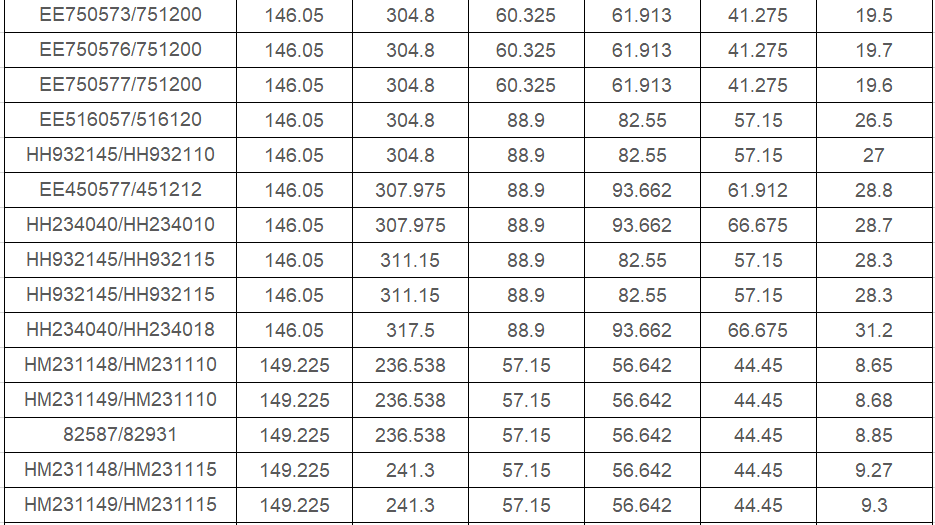

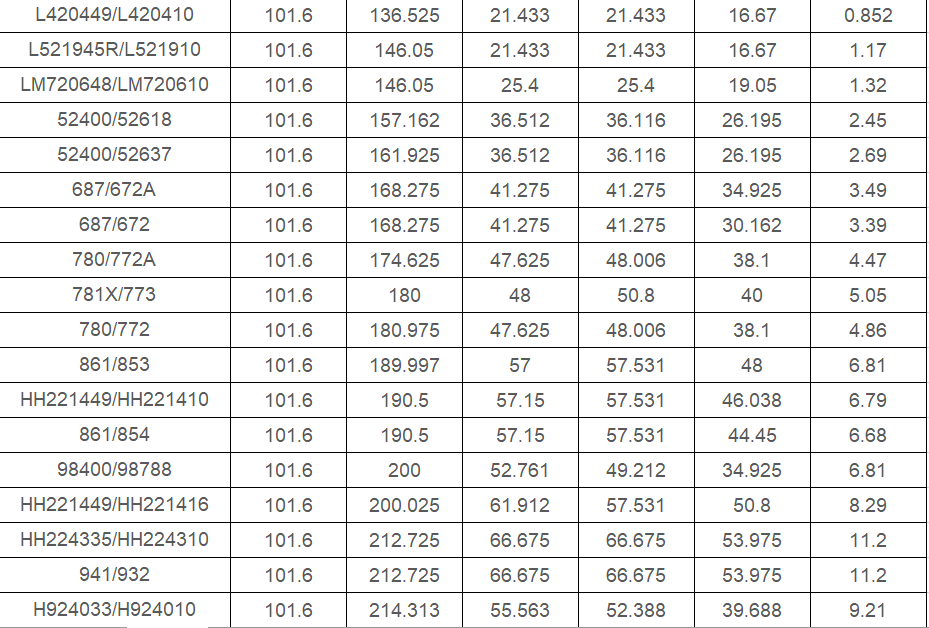

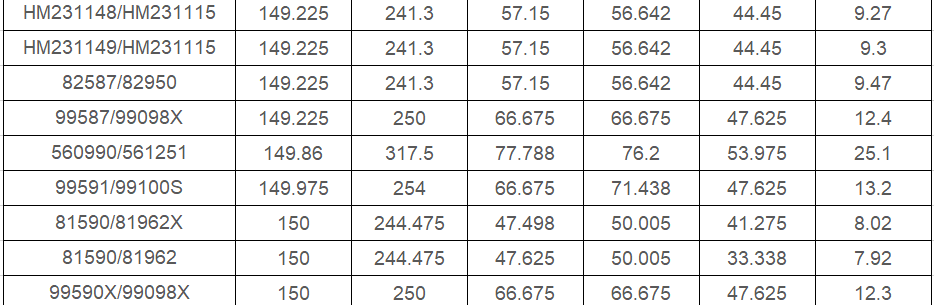

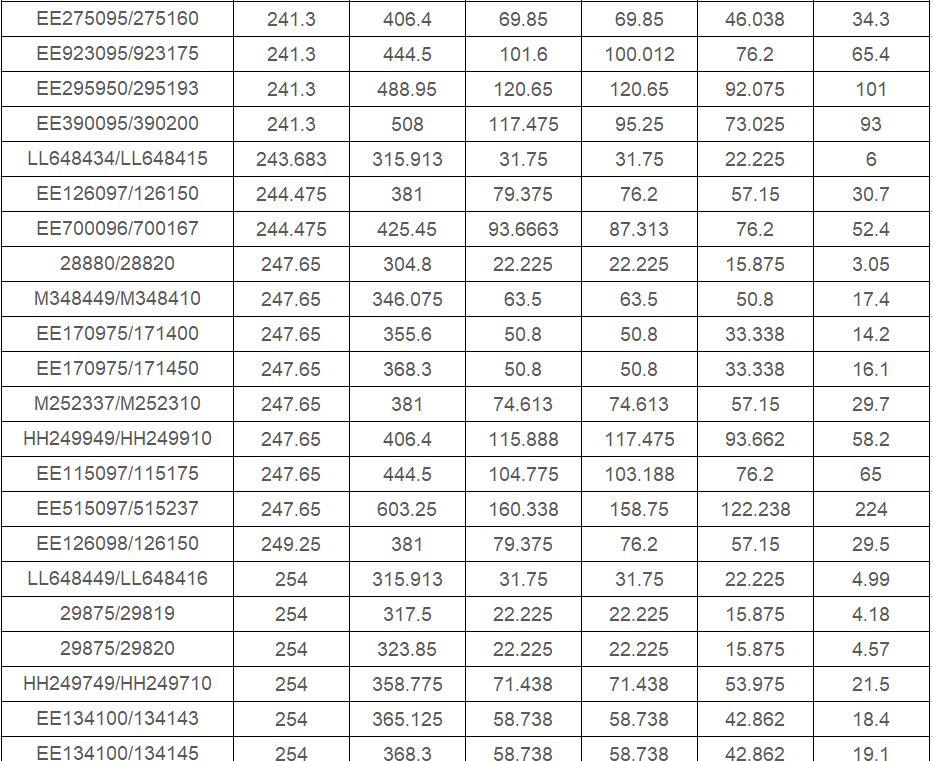

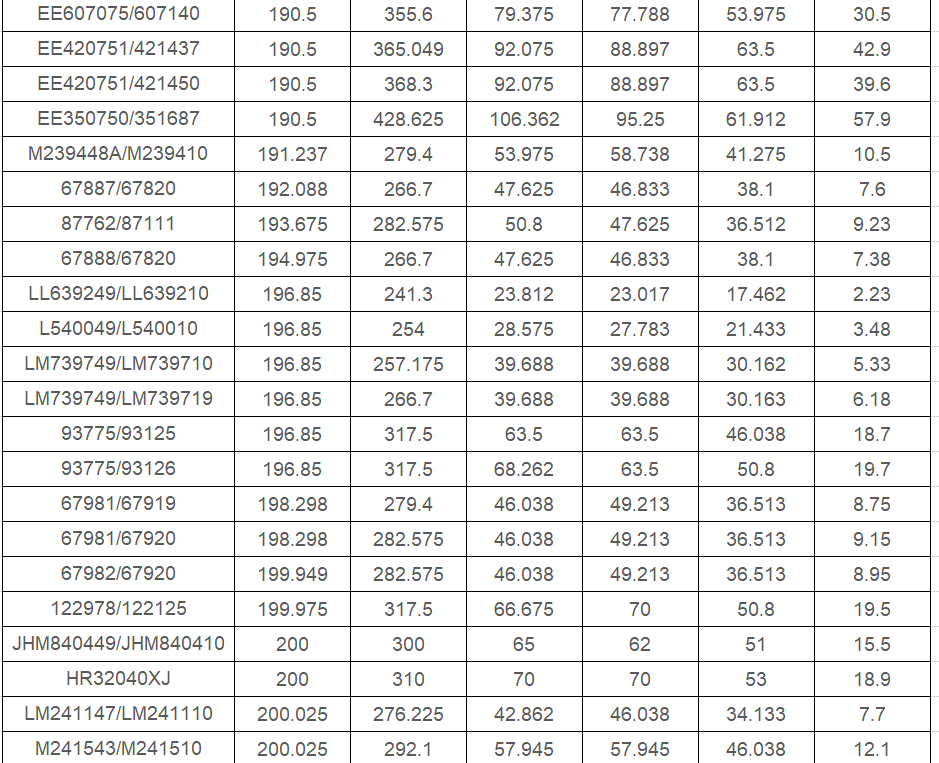

WSA taper roller bearings are manufactured both in standardized (metric and inch sizes) and in non-standardized constructive version. The metric single bearings have standardized dimensions as listed in ISO 355:1977 and those designated with prefix J conform to American AFBMA 19.1/1987. The inch size bearings conform to American AFBMA 19/1974. The taper roller bearings can carry only single direction axial loads. Under pure radial loads, an axial force is induced within the bearings so that they cannot be used singly and a second bearing is required. A correct operational clearance or preload has to be identified for the correct performance and reliability of the application. WSA taper roller bearings have pressed steel cage as standard. For large size and/or heavy engineering applications, the steel pin-type cage and case hardened carburizing alloy steels can be considered.

WSA single row taper roller bearings can also be produced with a rib on the outer cup as a flange to be used when the housing cannot be manufactured with shoulder, but only with a passed through hole so that, in this case, axial location can be provided by the bearing cup. When the load carrying capacity of a single row is inadequate or where the load has to be located in both directions, WSA produces the single row taper roller bearings as ready-to-mount matched pairs. The matched pairs, generally metric sized, in "O" back-to-back (designation DB) or "X" face-to-face (designation DF) arrangements, locate the shaft in both axial directions and the optimum axial play in the two bearings is adjusted and guaranteed after mounting.

In case of taper roller bearings, clearance should be in radial direction, but it is measured and adjusted in axial direction. WSA paired matching sets are made to normal and CLN class tolerances as standard corresponding to ISO 492:1986. The tolerances of the total width of the pair are not standardized, but an international common specification is applied. The matched pairs of taper roller bearings incorporate pressed steel cages guided on rollers.

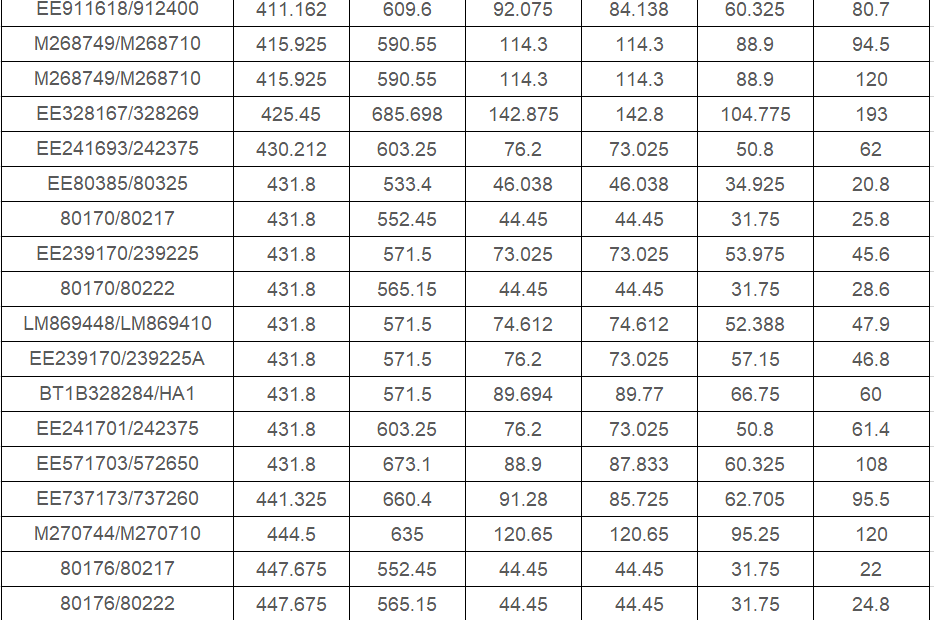

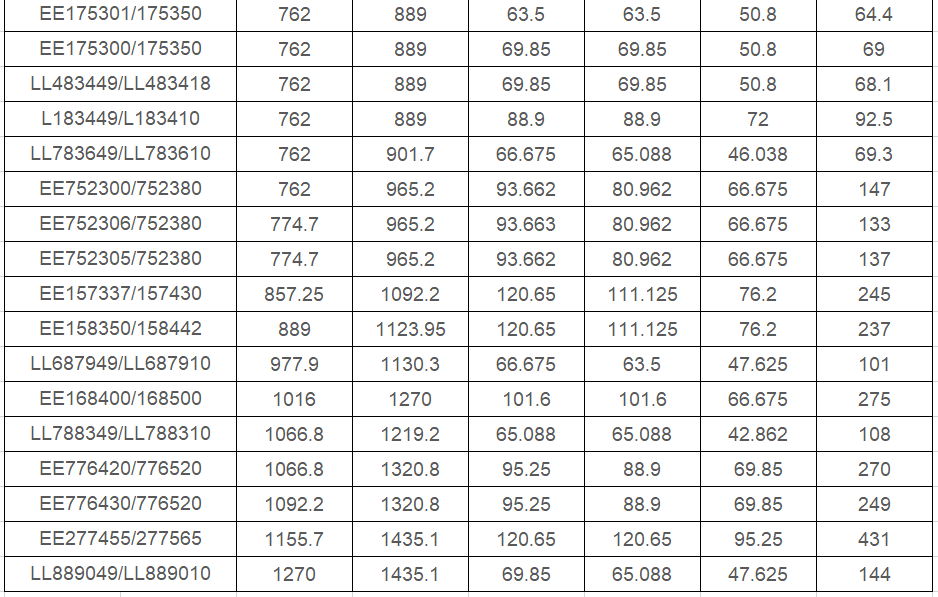

|

|

| Metric System | Imperial System |

More....

To ensurethe production of top-notch bearings, WSA Bearing Company adheres strictly to S0 9001 qualitystandards at every stage of manufacturing. We go the extra mile to guarantee product excellenceby implementing rigorous control measures for all incoming raw materials, with each materialhaving its composition archived and documented. Only qualified products proceed to the nextproduction process, which includes thorough inspections using cutting-edge equipment suchas metallographic testing devices, Oxford roughness profile analvzers, fluorescent flaw detectorsuniversal microscopes,and coordinate measuring machines(CMM).

WSA bearing line includes cylindrical roller bearings (single row, double row, and four-row), deep groove ball bearings, tapered roller bearings, spherical roller and ball bearings, angular contact ball bearings (single row and double row), thrust roller and ball bearings, all kinds of split bearings and non-standard bearings, widely used in industries such as aerospace, military, railroads, commercial vehicles, industrial manufacturing, ships, machine tools, metallurgical plants, motors, and agriculture. We are dedicated to providing our customers with the highest quality products and services. Our team of experts is constantly innovating and developing to ensure that we remain at the forefront of the industry. Contact us today to learn more about our exceptional products and how we can assist you with your bearing needs.

Contact: Mrs.Catherine

Phone: +86 15140413495

E-mail: sales@wsabearing.com

Add: Wawo Industrial Zone, Wafangdian City, Dalian China