Deep groove ball bearings are particularly versatile bearings. They are of simple design, are non-separable, can operate at high speeds are robust in operation and require little maintenance. These properties together with the moderate price make deep groove ball bearings the most popular of all rolling bearings.

Deep Groove Ball Bearings

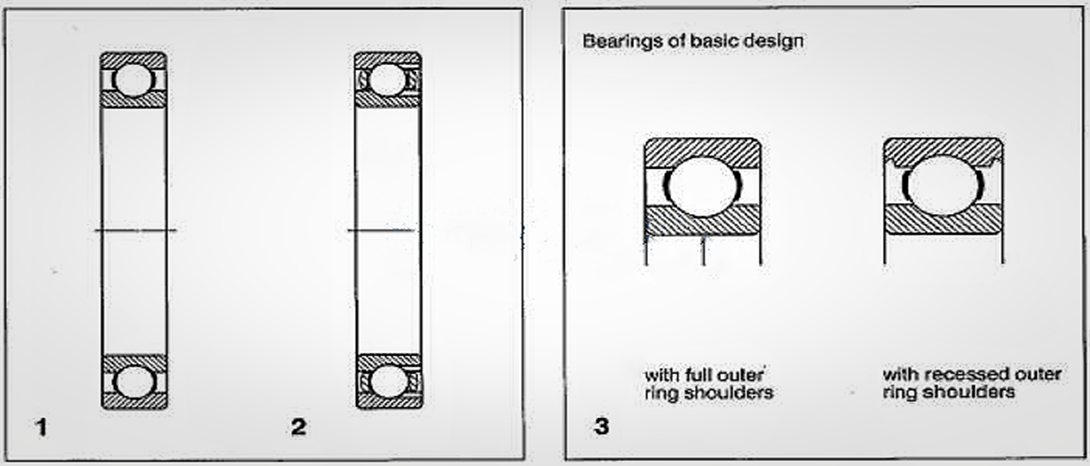

WSA produces many designs and sizes of deep groove ball bearing. Single row bearings without filling slot (1) - Conrad assembly-constitute the majority. The large bearings with filling slot (2) have been designed for special applications and only relatively few sizes are manufactured.

Deep groove ball bearings without filling slot

These single row bearings have deep raceways and close osculation between the raceways and balls. Therefore, in addition to radial loads, they are able to carry axial loads in both directions even when operating speeds are high.

For manufacturing reasons the open(unsealed) bearings sizes also produced with seals at both sides as standard may exhibit seal retention grooves in the outer ring(3).

Sealed bearings

The most popular sizes of deep groove ball bearings are also produced in shielded (non-rubbing seals) and sealed (rubbing seals) versions.

Bearings with shields or seals at both sides are supplied as standard charged with a lithium base grease which has good rust inhibiting properties and is suitable for operating temperatures in the range -30 to +110℃The bearings are maintenance free.

The sealed bearings can also be supplied to special order lubricated with greases which are suitable for other operating temperature ranges, eg. -40 to +150C. The grease quantity used is appropriate to the bearing size and normally takes up 25 to 35 % of the free space in the bearing.

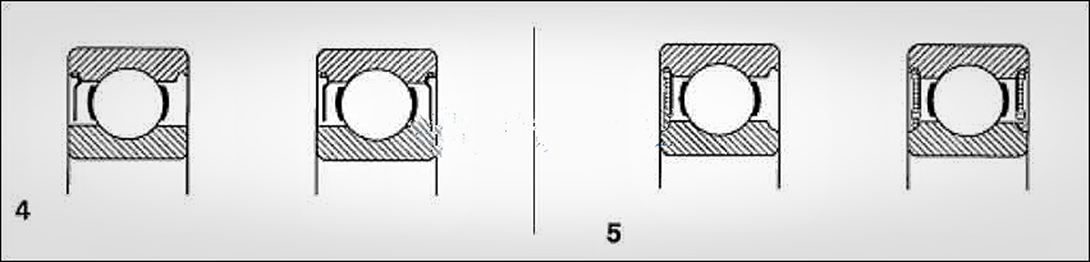

Bearings with shields

These bearings are identified by the desig nation suffix Z or 2Z and incorporate sheet steel shields. There is a small gap between the shield and the land of the inner ring shoulder(4).

The bearings are primarily intended for applications where the inner ring rotates There is a danger of lubricant leakage if the bearings are operated with rotating outer ring at relatively high speeds.

Bearings with seals

The rubbing seals of bearings identified by designation sufix RS1or 2RS1seal against a recess in the inner ring face(5). The seals are made of oil and wear resistant synthetic rubber witha sheet steel reinforcement. The operating temperature range is -40 to +120C. The seals are inserted in grooves in the outer ring without causing deformation but forming a tight seal. The sealing lip exerts a slight pressure on the inner ring land.

Under extreme operating conditions, e.g. at high speeds or high temperatures grease may leak from under the seal lip For bearing arrangements where this would be a disadvantage special design modifications must be made.

SPECIFICATIONS | ||

Series | Inner Diameter (mm) | Variant Structure |

61800 | 110~1280 | Z, 2Z, RZ, 2RZ |

61900 | 100~1280 | Z, 2Z, RZ, 2RZ, N, NR, ZN, RZN |

16000 | 100~1000 | |

6000 | 100~1180 | Z, 2Z, RZ, 2RZ, RS, 2RS, N, NR, ZN, RZN |

6200 | 100~400 | Z, 2Z, RZ, 2RZ, RS, 2RS, N, NR, ZN, RZN |

6300 | 100~400 | Z, 2Z, RZ, 2RZ, RS, 2RS, N, NR, ZN, RZN |

6400 | 100~400 | N, NR |

More....

To ensurethe production of top-notch bearings, WSA Bearing Company adheres strictly to S0 9001 qualitystandards at every stage of manufacturing. We go the extra mile to guarantee product excellenceby implementing rigorous control measures for all incoming raw materials, with each materialhaving its composition archived and documented. Only qualified products proceed to the nextproduction process, which includes thorough inspections using cutting-edge equipment suchas metallographic testing devices, Oxford roughness profile analvzers, fluorescent flaw detectorsuniversal microscopes,and coordinate measuring machines(CMM).

WSA bearing line includes cylindrical roller bearings (single row, double row, and four-row), deep groove ball bearings, tapered roller bearings, spherical roller and ball bearings, angular contact ball bearings (single row and double row), thrust roller and ball bearings, all kinds of split bearings and non-standard bearings, widely used in industries such as aerospace, military, railroads, commercial vehicles, industrial manufacturing, ships, machine tools, metallurgical plants, motors, and agriculture. We are dedicated to providing our customers with the highest quality products and services. Our team of experts is constantly innovating and developing to ensure that we remain at the forefront of the industry. Contact us today to learn more about our exceptional products and how we can assist you with your bearing needs.

Contact: Mrs.Catherine

Phone: +86 15140413495

E-mail: sales@wsabearing.com

Add: Wawo Industrial Zone, Wafangdian City, Dalian China